Launching a new product is a daunting task for any entrepreneur – financing, marketing, sales, distribution, customer service – oh and product development. In product development alone there are so many technical disciplines involved, and even more steps.

But the same thing that makes product development daunting is also what makes it so exciting. At Ventrify, we’ve built a process to shape ideas into products that people love – and honestly, even though it’s still a work in progress, we’re proud of it.

There’s a lot of uncertainty to in product development – we know. In fact, we thought it wasn’t that complex to start with, so we did it, and we made mistakes. We learned and overhauled our design process. Then, we did it again and again. And after many iterations, we narrowed in on a process that we believe is the most efficient way to develop custom, new hardgoods and consumer electronics on a budget.

A process that allows flexibility, but also provides structure. One that allows quick iterations, and nimble design changes, while doggedly pushing towards an intentional end-goal.

In today’s article, we’ll talk about:

- What type of products our design process is meant for

- What types of teams this process is built for

- The Ventrify Process

- What didn’t work: The evolution of our process, what we tried before, and why it didn’t work

- Summary

What types of products our design process in meant for

This article will focus on hardgoods and consumer electronics using relatively established technology and limited resources.

Why hardgoods and consumer electronics products? Well, if you’re building an engine, it’s going to be different. And if you’re building a boiler, it’ll be different too. We’re talking about products you’d find in Best Buy or a Home Depot. That’s where the majority of our experience lies, so that’s what we’ll be focusing on in this article.

Now, what does relatively established technology mean? Well, if your PHD thesis is on a breakthrough physics phenomenon, you will have to spend a lot more time on R&D (research and development) than a new electric skateboard or air purifier. We’ll focus on the latter.

What types of teams this process is built for

We’ll also preface our article with a note on resources: we’ve built this process for a small team working on a budget. This is meant for entrepreneurs and startups, not companies with 100+ employees and a $10M budget.

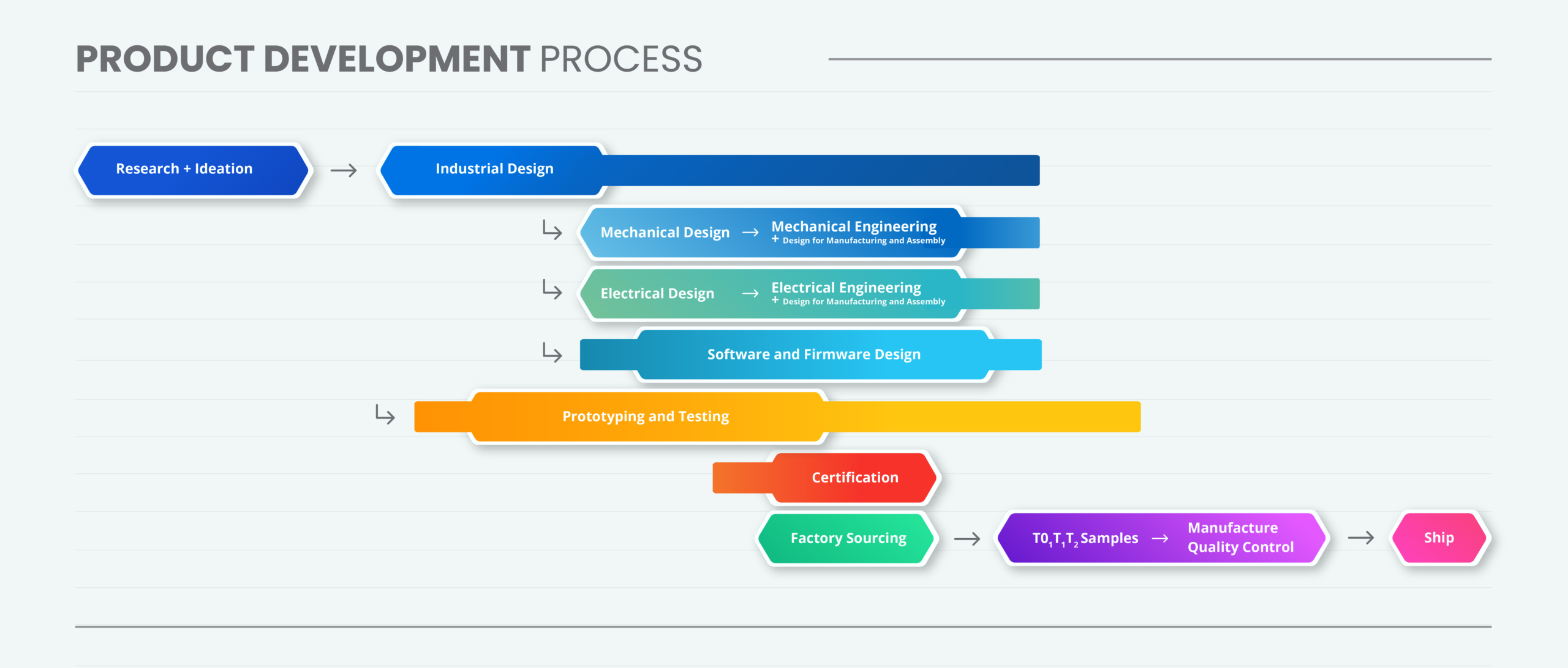

That being said, this is a multi-disciplined journey. Unless you have at least 1 person on your team that is dedicated to only product development, we don’t suggest you try this on your own. Our development team has 1 industrial designer who doubles as a project manager, 1 mechanical engineer, 1 electrical engineer, and 1 sourcing manager that all act as one team.

One team could accommodate 2 more mechanical engineers and 2 more electrical engineers depending on the types of projects. For startups that don’t have 1 client like we do, but are going to market themselves, we recommend having a product manager on the team.

Note that our team doesn’t include software expertise. We’ve found software to be an extremely broad domain on its own and have found better success in partnering up with software-dedicated teams on projects, so our process does not include the software development.

Working with the Right Framework: The Ventrify Design Process

This is the process we have optimized at Ventrify over the last four years to bring concepts from idea to fulfillment ready product.

Phase 1: Discover and Ideate

In this stage, we understand the problem, ideate solutions and visualize them through industrial design sketches. Then we wrap them up by creating a product requirement document. This establishes the base on which the whole product is built. Phase 1 consists of 3 parts:

Understanding the end-user, their problem, and the greater market need.

You have to know your end users intimately. This is the person who uses your product for its intended purpose.

- What are they doing?

- Where are they doing it?

- What do they value and what are they frustrated about?

- What alternative solutions do they currently have?

We’ve found answering these questions, helps with answering many design questions later on.

Ideating solutions and visualizing with sketches

After doing the research and understanding the context, the whole Ventrify team comes together to discuss and ideate solutions to the problem. If there is an original concept, this is the time to consider it and evaluate it against alternatives – the good, the bad, its appeal, and how to make it better.

Then, we take the best ideas and combine them into a final product concept that we will bring to life through industrial design sketches or renders.

Building a product requirement document

With thorough research and a clear product concept, you can now effectively define success in measurable ways. We translate our research and visuals into measurable targets. These product requirements allow us to estimate the time and cost required for the remainder of the project.

The parameters defined, and not defined, are based on what is important to the end user and the client. Defining these requirements is key to overcoming a common pitfall of design – scope creep (more on that later).

As the product’s founder and head cheerleader, you will be tempted to add features as the development progresses. By putting together a product requirement document, you can focus on intentional defining success at the start, and prevent endless design changes.

Remember, the first version of a product will always have room for improvement. This is what future product versions are for. Having these parameters in place at this stage will help move the design forward and drastically decrease timelines.

Doing a thorough Phase 1 has a disproportionate influence on the product design cycle. Changes in later stages require significant rework, so doing this first phase well is how we’ve cut our design timelines by as much as 50%.

Phase 2: Design and Prototype

Phase 2 is all about making sure it will work – design, built, test, repeat. Let’s look at these 3 parts:

Conceptual design: analyzing & solving key design challenges.

Here, we define key design elements and address challenges individually prior to integrating them into the full design. We do this with complex mechanical systems, breaking them into smaller, more manageable sub-systems. If your product has electronic requirements, we break them down the same way.

By breaking them down into smaller sub-systems, the design challenges become more approachable and less daunting. This also makes it a lot easier to estimate the time needed to address each challenge.

Prototyping the mechanical and electronic systems.

At this stage, we translate the design into mechanical and electrical systems. We model these systems using appropriate design tools, then plan, source, and build prototypes.

Depending on the prototype, we often defer to 3D printing because it is so flexible. Quick note on 3D printers: although having a 3D printer is very affordable and it is extremely versatile, misbehaving printers can waste a lot of time, do your research before deciding to do this in-house.

For electronics, we build out the design with a breadboard or a raspberry pie to make sure it works before moving to something more compact and custom like a pcb (printed circuit board). If your product needs software to run, this can get complex quite quickly and software has its own development cycles. For this stage in prototype testing, we simply build a sample interface using a tool like Figma.

There are 2 types of prototypes, functional and aesthetics. Functional prototypes will do the intended function but maybe a different shape, size or look. Aesthetic prototypes will look and feel like the product but won’t function properly or at all. Learn the ins and outs of prototypes at our blog, Prototyping in New Product Development Today.

Testing & Iterating

We test early prototypes quickly, iterating on changes as necessary and test them against key defined requirements from the product requirement document.

Most testing at the beginning can be done internally with the testing team or with friends and family. Since you’ve defined what your end users need, explain it to your testing team for context. Later on with higher fidelity prototypes, it is ideal to test with your end user.

When testing, watch how your product and its features are understood and used. Try not to make assumptions – instead, ask lots of questions, and try to understand the “why” behind what happens. Recordings help for later reference but be sure to ask permission.

If your prototype isn’t fully functional or the different parts of the system are not yet integrated, describe to them what would happen if they touch a button or pull a lever. Walk them through the functionality and try to get as much insight as possible.

Phase 2 is iterative within itself. This means the results in testing need to define the updates in the conceptual analysis, and the new prototypes should address previous issues.

Starting conceptual will help to iterate fast and not spend too much time on something that may not work. However, iterating fast allows you to narrow in on what works and get more detailed in addressing challenges and design concepts. Phase 2 is heavily influenced by the type of product you are working on, the systems in place, and the project requirements.

You know you’re ready to move to Phase 3 when all design features of the product have been set.

Phase 3: Engineer & Design for Manufacture

Phase 3 is all about getting the design production ready. This entails choosing a factory so that the manufacturing details can be determined.

Design for Manufacture and Assembly (DFMA)

This is the Design for Manufacturing Assembly (or DFMA) stage. Here we revisit the electronic and mechanical systems to optimize them for ease of manufacture, cost, reliability, and other product priorities. This means choosing the best manufacturing processes for your components and optimizing for that design process.

Once you have chosen a factory (you should have at this point), you should also work with them to accommodate their requirements as well as work with their in-house experts to implement any suggestions they may have (engineers at factories are often very specialized as they work in 1 environment for a long time and will have invaluable advice in that realm).

This step is also where you build your drawing package, export CAD files for the factory, and provide renders.

Manufacture Preparation

As you prepare to ship your product to do final testing and certification, it’s time to focus on the support material – product packaging and documentation packages.

For product packaging, consult with marketing as the “first impression” and “unboxing experience” can be very important but will depend on your market positioning and your distribution strategy.

Instruction manuals don’t always seem necessary, but can go a long way when limiting liability, targeting a less intuitive audience, and reducing the number of customer support emails you get. Remember, this doesn’t necessarily have to be printed, but make it visible and easily accessible.

Testing (and Certification if necessary)

Although calculations are great, you still need to make sure that the final product will withstand the theoretical design conditions.

This testing usually happens in highly controlled environments to ensure the design conditions are met. This can be done instead of, or in preparation for, certification. Certification is done by a variety of third-party labs and should be contacted early to gauge time and cost associated.

Learn more about the types of certifications your product may need at our blog, What Certifications are Needed for My Product?

Phase 3 also changes significantly based on the type of product and the requirements we have set out.

Phase 4: Production Management & Logistics

When you are done with Phase 3, you are ready to oversee production, ensure quality control, and manage the logistics.

Bonus: Find the best factory for your product needs

(Although this should be done during Phase 3, it fits better in this category).

Finding a factory involves searching and qualifying the best factories for your needs. There is no overall best factory, but there is one that is best suited for your project. Remember, your project will have specific priorities, whether it’s cost, quality, or time. Also, the factory you choose should fit your order size (unit quantity) and allow for future growth.

Ideally, you want a factory that has created similar products – one that uses similar materials, similar processes and is of similar complexity. This allows you to gauge the quality of the work that the factory does and allows them to use their valuable experience for your project.

When searching for a manufacturing partner, consider talking to at least 20 different factories & narrow down to the best 2-3. The initial number of factories you will need to reach out to will be high because of the low response rate, so more is better to start.

At Ventrify, we look for factories all across the world. For high-volume manufacturing, China Vietnam, and Taiwan are the leaders. But with China’s strict Covid-19 restrictions and the rising cost of shipping, North American factories are getting more and more attractive. Again, everything comes down to your project priorities.

Walking through the factory prior to making the final decision will allow you to see typical working conditions. It is important to know that your product is coming from a safe and respectable working environment. We always have someone from our team visit the factory – it helps build trust with the factory and works as the basis of a strong relationship.

Overseeing production and ensuring quality control

During your manufacturing run, it is critical to have third-party quality control set up to ensure that any detailed requirements are carried out.

Most experienced factories will offer in-house quality control but there is no real incentive for them to find and address these issues (especially if it your first time working with them). Unfortunately, they can often overlook quality control issues. It is best to use them in addition to a third-party dedicated contractor.

Mismanaging production and quality control can mean wasting all the hard work you dedicated to the design, so don’t let your guard down just yet.

Logistics

Logistics refers to managing the vendor contracts, timelines, and payment for trucking from factory to port, export management, shipping (or air freight), import management, trucking from port to train station, train transport, and trucking from train to fulfillment center.

Because there are so many moving parts that need to be coordinated perfectly, we often work with a specialty logistics company to make sure this process goes as smoothly as possible.

As we come off the back-end off the Covid-19 pandemic, there are many horror stories surrounding supply chain management. As a result, there has been a big push to onshore production, but this move is highly dependent on the industry you are in and the product you are making. We recommend you do your own research on this topic before starting as it is constantly changing landscape.

That’s our process in a nutshell!

There is, of course, a lot that changes depending on the type of product, the complexity, and the requirements of every specific project. But before you dive into developing your own product, read about our biggest stumbling blocks from the early days:

What didn’t work: the evolution of our process, what we tried before and why it didn’t work (our mistakes)

Staying aware of these before starting the project will help you avoid expensive mistakes and long delays.

Unclear Scope (aka scope creep)

Scope creep is a common beast.

Whether it’s out of excitement, a desire to make your product better, a bit of perfectionism, or just a lot of feedback you want to implement, there are always reasons and opportunities to increase the scope of a project.

Sometimes, it is warranted, but often, an unclear scope leads to scope creep. Having a well defined scope (read: have a good product requirement document) can go a long way to keeping you on track. This plays a huge factor in both time and cost.

Not Planning Ahead

It sounds silly now, but in our early years of product design, we split every part of the product design process into each own step (9 steps at one point) and did them consecutively. That didn’t work for many reasons, but one of the consequences was that it was easy to focus on work at hand.

We justified it by saying it would improve focus, decrease task switching, and result in more progress. But it only took one time signing up for a certification lab and being put into a 3 month que before we changed that.

Plan ahead.

Planning for every detail

After not planning enough, we over-corrected and began to forecast the whole project from the start. It was part of an initiative to help with quoting lump sum projects.

But the nature of the design process is it is unpredictable. Change happens. Testing never goes as planned. There is almost no way to forecast how many design iterations you will end up doing. You have to stay nimble.

We’ve found that a product requirement document strikes a strong balance – it helps define the end goal, but allows us to be flexible in getting there. We’ve also moved away from lump sum projects for this reason.

Summary

Product development is broad and complex, but for hardgoods and consumer electronics built on a budget, the Ventrify Design Process is a guide to an efficient and methodical product launch.

Trust the process, avoid our mistakes, and make something great. Good luck!

If you enjoyed this article, you might also enjoy our other insights: https://ventrify.ca/blog/

About the Author

Ventrify is a product design and manufacturing firm that helps entrepreneurs bring product ideas from concept to market. We take in fledgling ideas and bring them through our iterative design process to create products our clients can be proud of. Then, we work with manufacturing facilities worldwide to bring our clients the highest quality products at competitive prices.

If you have questions about the Ventrify Design Process or need help with your product design, reach out to us through our Website, Facebook, or LinkedIn.